SERVICES

Our world-class customer service isn't automated... It's automatic

All Services

Let’s make something great together.

Do you need help with a metal fabrication or finishing project? Reach out to see how we can help you succeed.

Tool & Die Development

For over 50 years, Stampings of Minnesota has been providing our customers with In-house tool & die services. With decades of experience to draw on, our skilled craftsmen are the people you need to turn to for one-to-one customer service.

From prototyping to production runs, Stampings of Minnesota works closely with our customers to develop an optimal design that provides the functionality they require at a price within their budget.

Since we have a wide range of customers in the aerospace and medical device industries, we offer stage and progressive tool designs that can accommodate tolerances of +/- .001. Our customers in telecommunications and computer networking frequently require multiple-part assemblies that must be produced with multiple groups of tools. And, our customers in the consumer products and automotive industries rely on our prototyping capabilities as a dependable partner in their product development stages.

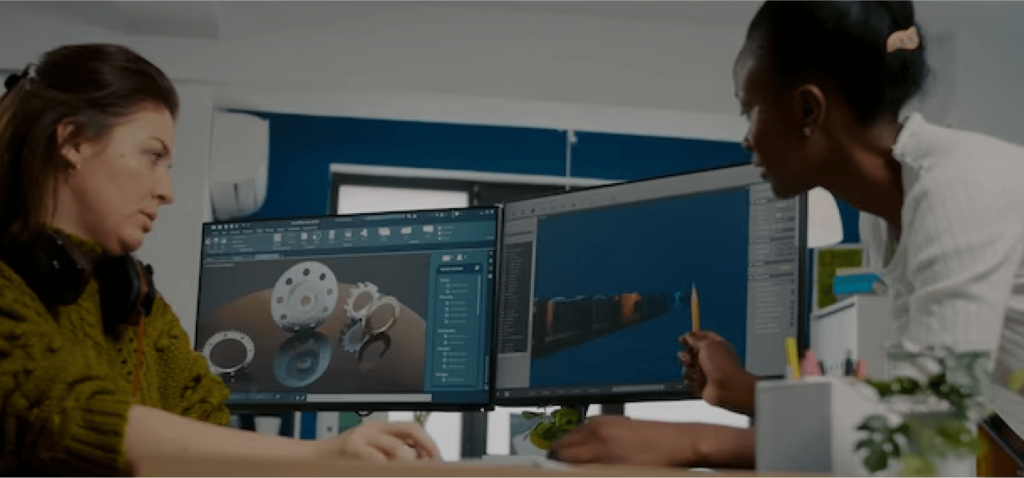

Our history of investing in state-of-the-art tool and die equipment enables us to move your new project from a concept into production parts with unsurpassed speed and accuracy. In 2005 we added (2) Fanuc Wire EDM machines that provide unsurpassed speed and accuracy in our production process. Our equipment can provide a cutting speed of .3 inches per minute and can work within a tolerance of +/- .0002 of an inch. As a result, our development time and product quality continue to be industry standards that are unparalleled on this continent and in Asia. Our systems can turn your file drawings (.dxf, .dwg, .step, or .igs) into production parts with the latest computer and software advances. Currently, our technical experts utilize the following programs:

- Solidworks

- CadKey

- Keycreator

- Emetrix

- SMP

Why choose this service?

We work with your engineers to create the products that fit your needs.

Our prototyping capability make us a valuable partner in product development.

Our tool department has unmatched experience and is trained in cutting edge technology.

Equipment

Bridgeport Vertical Milling Machines (4)

Clausing 20" - Drill Presses (2)

Fanuc Wire Cut EDMs - Model 1iC-S/AWF (2)

Fodick Drill (1)

Gantry 1 Ton Portable Crane (1)

Grob Band Saw (1)

Hardinge Lathe (1)

Harig Surface Grinder (1)

Kent Surface Grinders (2)

LeBlond Lathe (1)

Wilton Band / Cut Off Saw (1)

View our Equipment List for all our fabricating machinery, metal stamping process, and sheet metal stamping presses.

Quality Materials

Tolerances are +/-.001; true position .001; hole size +/-.0005.

Get a Quote Today!

Our team would be happy to answer any questions about our services, capabilities, machines and more. Reach out and a team member will contact you.